- Home >

- Products >

- Technical Highlight >

- Vol.7: Kobelco's ARCMAN™ welding robots and SENSARC™ power sources: unsurpassed performance across many applications >

Technical Highlight Vol.7

Kobelco's ARCMAN™ welding robots and SENSARC™ power sources: unsurpassed performance across many applications

The Welding Business of Kobe Steel, Ltd., is the worldwide manufacturer that provides total welding solutions, including arc welding consumables, welding robots and power sources through its independent research and development.

Over the years, Kobe Steel has developed comprehensive robotic arc welding systems, comprising not only the robot, but the power source and peripheral equipment such as positioner and slider as well. In addition, customers are provided with welding procedures designed to meet their particular needs. This is one of Kobe Steel’s strong points. In this edition, we present and discuss the features of the ARCMAN™ series welding robots as well as the SENSARC™ series power sources.

The original ARCMAN™ models

The ARCMAN™ series welding robots are generally put to use on medium- and heavy-thick plates used in such fields as construction machinery, buildings steel structures, bridges, and rolling stock. Four ARCMAN™ models are available including the recently developed ARCMAN™-GS.

1. ARCMAN™-SR

This compact, lightweight robot lessens the weight of the entire system and requires less installation space. With high wrist torque comparable to the standard ARCMAN™-MP, it can be equipped with heavier torches, such as water-cooled or tandem torches.

2. ARCMAN™-MP

Kobe Steel’s best selling model, ARCMAN™-MP utilizes a standard water-cooled torch and is applied on medium and heavy plates. Welding application software as well as sensors for searching welding grooves can be installed. It can be equipped with a long torch for handling confined spaces, and, because of its high payload and wrist torque, a tandem torch or a plasma cutting torch.

3. ARCMAN™-XLmkII

Featuring the world’s largest arm, this robot’s motion range can exceed a maximum of 3 meters of reach, allowing the robotic system to be configured along a simple axis structure without a slider. Another advantage of this model’s long arm is the ability to access the deep part of a hollow workpiece, such as the basket of a hydraulic shovel.

The new ARCMAN™-GS

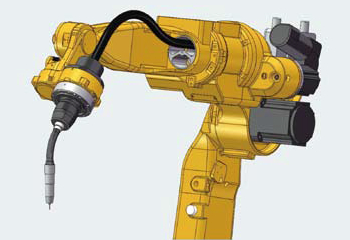

Figure 1 : ARCMAN™-GS shines in the medium and heavy plate welding.

Well-suited for welding medium and heavy plates, ARCMAN™-GS is the product of Kobe Steel’s wealth of experience in welding robotics; it was launched in September 2011. While its arm is equivalent in size to that of ARCMAN™-MP, its improved design features an arm with internal cabling as shown in Figure 1.

1. Background to the development of ARCMAN™-GS

The ARCMAN™ series robots have highly been reputed, particularly in the construction machinery field, where the robotic systems increasingly utilize robots mounted upon overhead-suspended sliders. Overhead suspension is forecast to spread more widely in the future as it provides better ease of access to large-scale workpiece as well as superior safety and operation efficiency as the machinery is removed from the ground.

In the welding of construction machines, the welding torch must be able to reach deep inside the hollow workpiece. Additionally, the robot teaching operation must be free from interference occurring between the torch and workpiece as well as between the torch cable and workpiece. For these reasons, the torch cables should be strung inside the arm. Because ARCMAN™-GS has sufficient motion range for an overhead-suspended system and features the cable-integrated arm suitable for off-line teaching, it is an excellent robot for such a demanding application.

2. Features of ARCMAN™-GS

Figure 2 : ARCMAN™-GS with the cable-integrated upper arm.

(1) Cable- or torch-integrated models are available to match system requirements

Two variations are available for ARCMAN™-GS: one with cables integrated with the upper arm, as shown in Figure 2, and the other in which the torch is integrated with the wrist axis, as shown in Figure 3.

For the cable-integrated upper arm type, a wire feeder is mounted at the rear side of the upper arm; the torch cables extend from the wire feeder through the cable hole that runs alongside the upper arm. The torch body is supported at the wrist axis.

For the torch-integrated wrist axis type, the wire feeder is not mounted on the robot but is installed peripherally. The torch cables extend from the wire feeder on a cable hanger to connect to the torch body, which is supported at the wrist axis.

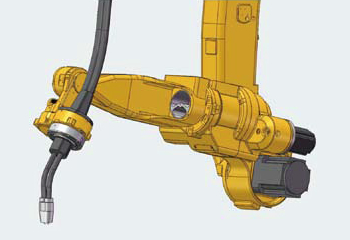

Figure 3 : ARCMAN™-GS with the torch-integrated wrist.

Figure 4 shows what can happen when the torch cable is not integrated with the upper arm: the cable dangling dangerously close to the inner rim of the workpiece can cause interference between the torch cable and the workpiece, and, over time, affect the durability of torch cable.

In this case, internal cabling could prevent interference between the torch cable and workpiece, allowing the teaching operation to be easily carried out. Also the cable-integrated model allows off-line teaching to be conducted on a personal computer because no unpredictable cable movement can occur.

Figure 4 : Example of robotic welding where the interference between torch cable and workpiece is about to occur.

If internal cabling is undesirable, the torch-integrated wrist arm model can be selected. With this model, the torch body is aligned at the center of the 6th axis, which allows accurate coordination of the torch with the movement of the robot, minimizing interference even if the torch is put into the narrow and deep part of the workpiece.

In the torch-integrated model, the wrist is cantilevered so as not to entangle the torch cable with the wrist, and the wrist axis motor is housed in the wrist frame so that the wrist edge does not protrude. This minimizes cable entanglement as well as interference between cable and workpiece during welding.

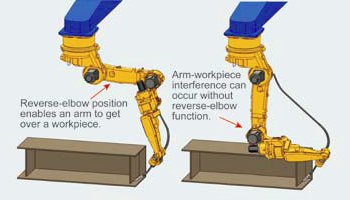

(2) Reverse-elbow positioning enables an operating envelope that is the largest in its class

In an overhead-suspended robotic system, the robot should be able to access as much of the workpiece as possible from above. Therefore, the robot’s operation envelope should be large and able to cover the area behind as well as in front of the robot.

With ARCMAN™-GS, the reverse elbow position enables the upper arm to bend behind the robot, as shown in Figure 5, expanding the motion range. This advanced function of the ARCMAN™-GS is only possible because the arm is as long as that of ARCMAN™-MP.

Figure 5 : Reverse-elbow position (left) can

prevent arm-workpiece interference with

overhead-suspended robotic system.

As illustrated in Figure 5, the reverse elbow positioning with ARCMAN™-GS enables easy access to weld lines that lie behind obstacles without interference between the arm and the workpiece. In contrast, conventional robots require complex sliding movements in order to achieve similar results and avoid interference. Because ARCMAN™-GS is capable of reaching inaccessible spots without sliding, the slider it does use is short, reducing the complexity and weight of the entire system.

Figure 6 : The multifunctional ARCMAN™-GS with an automatic tool-exchanger.

(3) Automatic exchange between tandem torch and single torch

Kobe Steel has supplied quite a number of ARCMAN™ series robots for tandem arc welding, and ARCMAN™-GS is particularly effective at this. With the tandem torch housed at the wrist axis center, the cable-integrated arm can extend into confined spaces that conventional robots would find impossible to tandem weld.

In addition, the tandem torch and single torch can be exchanged automatically with the installation of the automatic tool-exchanger, exclusively designed for ARCMAN™-GS. With this system, either tandem or single arc welding can be selected, depending on the shape of workpiece and the welding joint configuration. Figure 6 shows a robot with an automatic tool-exchanger.

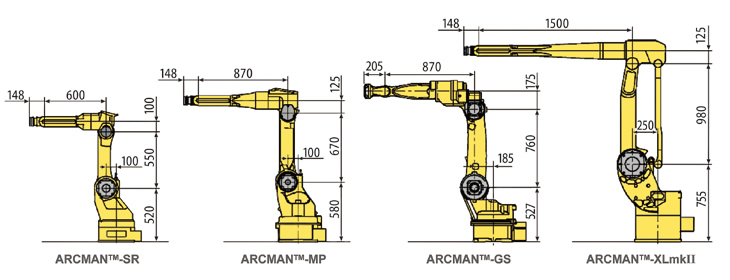

Figure 7 shows the structures and dimensions of the ARCMAN™ series robots, and Table 1, the specifications for the ARCMAN™ series manipulators.

Figure 7 : A lineup of ARCMAN™ series arc welding robots. (diagrams with dimensions)

A dedicated welding power source for robots: SENSARC™ AB500

| Items | Specifications | |

|---|---|---|

| Corresponding controller | CA type controller | |

| Maximum motion range for each axis |

S1 | ±170 deg |

| S2 | -100/+155 deg | |

| S3 | -210/+80 deg | |

| S4 | ±180 deg | |

| S5 | ±127 deg | |

| S6 | ±360 deg | |

| Maximum speed for each axis |

S1 | 2.09 rad/s, 120 deg/s |

| S2 | 2.71 rad/s, 155 deg/s | |

| S3 | 2.71 rad/s, 155 deg/s | |

| S4 | 6.98 rad/s, 400 deg/s | |

| S5 | 6.11 rad/s, 350 deg/s | |

| S6 | 10.47 rad/s, 600 deg/s | |

| Payload | At the end of wrist: 15kgs At the mounting position of wire feeder: 20kgs |

|

| Allowable moment of wrist for each axis |

S4 | 38.9 Nm |

| S5 | 38.9 Nm | |

| S6 | 7.35 Nm | |

| Allowable moment of wrist inertia for each axis |

S4 | 1.05 kg•m2 |

| S5 | 1.05 kg•m2 | |

| S6 | 0.038 kg•m2 | |

| Installation position | On floor or overhead-suspended |

|

| Manipulator weight | 286 kgs | |

| Painting color | Dull yellow | |

Kobe Steel’s SENSARC™ series is a lineup of welding power sources for CO2/MAG welding that meet a variety of applications. SENSARC™ AB500, for example, is a sophisticated power source exclusively for ARCMAN™ robotic welding systems for medium and heavy plate welding (see Figure 8). It is ranked as the highest quality model of the SENSARC™ series, offering multifunctional welding performance.

1. Innovations in key capabilities

SENSARC™ AB500 offers an 8 times faster arithmetic capacity and a 2.5 times higher control frequency as compared with conventional power sources, thereby establishing an innovative output waveform control by an advanced control rule.

The combined wire feeder is equipped with four driving rolls to ensure a 1.5 times stronger wire feeding force, thus increasing the maximum wire feeding speed to 30 m/min, which is 20% higher than conventional ones. In addition, the wire feeding stability has been improved by employing an encoder that detects motor rotation, a four-roll driving method, high precision digital control, and a quick response motor.

These advanced capabilities, as well as a stable and smooth arc start and easy wire feeding through wire touch sensing, shorten idle time, thereby improving the welding performance by ARCMAN™ robots. Table 2 shows the specifications for SENSARC™ AB500.

| Items | Specifications |

|---|---|

| Rated input voltage | AC200V/AC220V |

| No. of phase | 3 phases |

| Rated frequency | 50Hz/60Hz |

| Rated input power | 28.1kVA, 26.6kw |

| Rated current | 81A/74A |

| Rated output current | 500A |

| Rated load voltage | 45V |

| Output current | 30-500A |

| Output voltage | 12-45V |

| Maximum no load voltage | 86V/95V |

| Duty cycle | 450A-100% 400A-100% (Pulsed welding) |

| Outer dimension (WxHxD) | 370x685x665 (mm) (Input terminal head, eyebolt and hexagon bolt are not included) |

| Weight | 69kgs |

Figure 8 : SENSARC™ AB500: a multifunctional power

source for ARCMAN™ welding robots.

2. A variety of optimum welding modes for medium and heavy plate welding

| Shielding gas |

Welding method |

Kind of wire | Wire dia. (mm) |

|---|---|---|---|

| CO2 | Single, Without pulse |

Solid wire for mild steel | 1.2 |

| Flux cored wire for mild steel |

1.2, 1.4 | ||

| Flux cored wire for stainless steel |

1.2 | ||

| Single, REGARC™*1 |

Solid wire for mild steel | 1.2 | |

| Ar+CO2 | Single, Pulse | Solid wire for mild steel | 1.2, 1.4, 1.6 |

| Single, Pulse | Solid wire for mild steel | 1.2, 1.4 | |

| Tandem, Pulse | Solid wire for mild steel | 1.2 | |

| *1: REGARC™ is a unique pulse-current-waveform control process. | |||

SENSARC™ AB500 is equipped with, in addition to the innovations mentioned above, several new welding modes, including the Kobe Steel-developed arc welding process with unique pulse-current-waveform control. These modes are elaborately tailored to medium and heavy plate welding; thus, welding performance can be improved even in some of the more conventional modes as shown in Table 3.

3. Tandem-pulsed MAG welding applications

In 2001, Kobe Steel began marketing a robotic system that provides both high welding speeds and sound welds by using the two-electrode one-pool tandem arc welding technique featuring high deposition rates.

Through persistent research and development on the tandem arc welding method, an innovative welding current output control has been developed and applied to the present power source. With this technique, two tandem pulsed arcs are controlled in such a way that the pulse peak and base currents are synchronized between the two arcs, thereby increasing arc stability and reducing spatter.

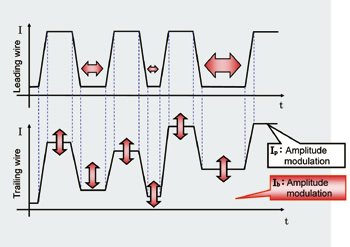

With SENSARC™ AB500, the arc length of the trailing electrode is optimized by the newly developed synchronous amplitude modulation control that increases or decreases the pulse peak and base current as shown in Figure 9.

Figure 9 : Conceptual diagram of synchronous amplitude

modulation control.

With this mechanism, SENSARC™ AB500 allows a wider range of welding parameters because the arc lengths of both leading and trailing electrodes are controlled adequately, preventing disturbance effects and maintaining the constant arc lengths. Furthermore, unlike conventional power sources, a change in the leading electrode’s welding parameter does not affect that of the trailing electrode; hence, welding parameters can easily be adjusted.

To obtain a stable arc and sound weld in one-pool tandem arc welding, control over the molten metal bulge generated between the two electrodes in the weld pool is essential.

With conventional power sources, when one electrode encounters a disturbance, the arc fluctuates, causing changes in arc length that affect the arc force, and this can cause the molten metal bulge to become unstable. And the destabilized bulge of molten metal affects the arc force of the other electrode, thereby causing an unstable arc.

By contrast, SENSARC™ AB500 can maintain stable arcs and cancel disturbances with the advanced high quality load-characteristic control.

Figure 10 : One-pool tandem arc welding with (top)/without (bottom) high quality load-characteristic control.

In Figure 10, the top picture shows a stable bulge of molten metal generated between the two electrodes by means of high quality load-characteristic control, thereby creating stable and low spatter arcs. In contrast, when load-characteristic control is not used, as shown in the bottom picture, the bulge fluctuates in shape, causing unstable arcs with much spatter.

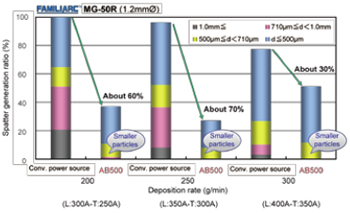

With SENSARC™ AB500, the high quality load-characteristic control reduces spatter generation by as much as 70% as well as spatter particle size, when compared with a conventional power source, as shown in Figure 11.

Figure 11: Spatter generation in tandem arc welding with

SENSARC™ AB500 and conventional power sources.

4. Advanced performances in other applications

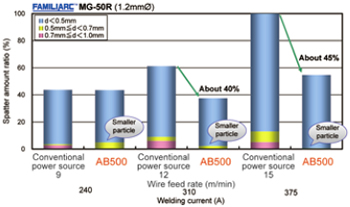

In pulsed MAG welding with solid wire for mild steel, arc stability and spatter generation can be improved (Figure 12) with some new technologies. For example, the immediate load-characteristic control as well as the high-quality disturbance-cancellation control can remove the instantaneous fluctuation associated with the fluctuation at the current-carrying point and the arc generation point on a welding wire, thereby reducing excessive arc force fluctuation.

With such advanced technologies, SENSARC™ AB500 can reduce the spatter generation ratio by up to 45% and spatter size, even at a high welding current of 300 A or more as is used commonly in the medium and heavy plate welding.

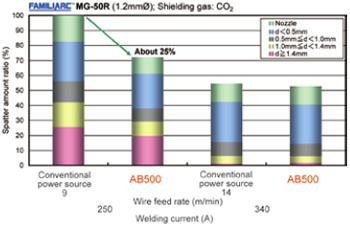

In CO2/MAG welding in the medium welding current range, where large spatter particles tend to be generated, the advanced technology for suppression of molten droplet vibration can reduce the spatter generation ratio by as much as 25% in comparison with a conventional power source as shown in Figure 13. With this technology, excessive droplet growth and vibration are restrained by changing the operating characteristics according to the amount of droplet growth. As a result, it prevents droplets from scattering and reduces the spatter generation ratio.

Figure 12 : Comparison of spatter generation ratio between

SENSARC™ AB500 and conventional power source by

pulsed MAG welding.

Figure 13 : Comparison of spatter generation ratio between SENSARC™ AB500 and conventional power source by CO2 welding.

In the next issue onwards, examples of field-proven applications of medium and heavy plate welding by using the ARCMAN™ series welding robots and the SENSARC™ series welding power sources will be discussed.

References:

[1] Kobe Steel, Welding Technical Report, Vol. 50, 2010-6

[2] Kobe Steel, Welding Technical Report, Vol. 51, 2011-9

Products

- Main Products

- Welding Consumables

- Arc welding robots

- Industries - Recommended Materials

- Welding Handbook Quick View

- Product Quick View & Highlights

- For HEAT-RESISTANT STEEL

- For STAINLESS STEEL

- For LOW-TEMPERATURE STEEL

- Product Highlight

- Catalog

- Technical Highlights

- Certification

- SDS ※English Only

- ARCMAN

- Welding Robot

- Software