- Home >

- Products >

- Main Products >

- Software >

ARCMANTM

Off-line Teaching System

- Shortens required training time

- Cuts cost

Production Support System

- Facilitates gathering and amassing of information

- Facilitates production process improvement

Off-line Teaching System

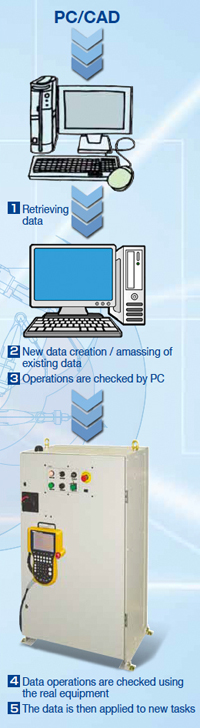

Information on tasks and program development : flow of operations

- Retrieving information on tasks

Information (data) on tasks created via CAD can be re-used.

The newly created data forms the basis for new programming. - New data creation / amassing of existing data

Enter weld length and welding conditions.

Compiling data is the first step to retrieving data and re-using it.

Prepared / compiled data is given a new name and saved. - Operations are checked by PC

Newly saved data is checked by PC. At this time, the data is inspected for bugs, interference, etc. - Data operations are checked using the real equipment

The completed data is sent to the controller for testing on real equipment. - The data is then applied to new tasks

Once operations are checked with real equipment and no problems are found, the data is applied to real operations.

Information on tasks / program compilation, checking, operations

- Retrieving information on tasks

- Information (data) on tasks created via CAD can be re-used.

Data is derived by CAD and re-used in data compilation for new tasks.

We employ software that converts and reads converted 3-dimensional CAD data (STL format) (optional). - The newly created data forms the basis for new programming.

Use of past items shortens the time required to produce data.

- Information (data) on tasks created via CAD can be re-used.

- New data creation / amassing of existing data

- Enter weld length and welding conditions

To create new data starting from zero, data on weld length and welding conditions are both entered. - Compiling data is the first step to retrieving data and re-using it.

The process of retrieving or re-using data begins with data compilation. - Prepared / compiled data is given a new name and saved.

New data or data updated in the compilation process is given a new name and saved under that new name.

- Enter weld length and welding conditions

- Operations are checked by PC

- Newly saved data is checked by PC.

Newly saved data must be checked to ensure that it runs as expected.

This checking process can be done with this software on a PC.

- At this time, the data is inspected for bugs, interference, etc.

This software an detect any problems that may occur during real operations, including bugs, failure of weld torch, robot arm problems, etc.

Bugs and failure problems can be detected on the PC screen, improving quality of the data by correcting as necessary.

- Newly saved data is checked by PC.

- Data operations are checked using the real equipment

- The completed data is sent to the controller for testing on real equipment.

Where completed data that has been confirmed bug-free is saved, it is sent to the controller. It is then tested on real equipment(ARCMANTM).

(When the data is sent, it is converted for use in a program to operate ARCMANTM).

- The completed data is sent to the controller for testing on real equipment.

- The data is then applied to new tasks

Once operations are checked with real equipment and no problems are found, the data is applied to real operations.

Once operations are checked with real equipment and no problems are found, the data is applied to real operations.

If there are no problems with use of the data on real equipment, the program name is specified and the data is applied to real operations.

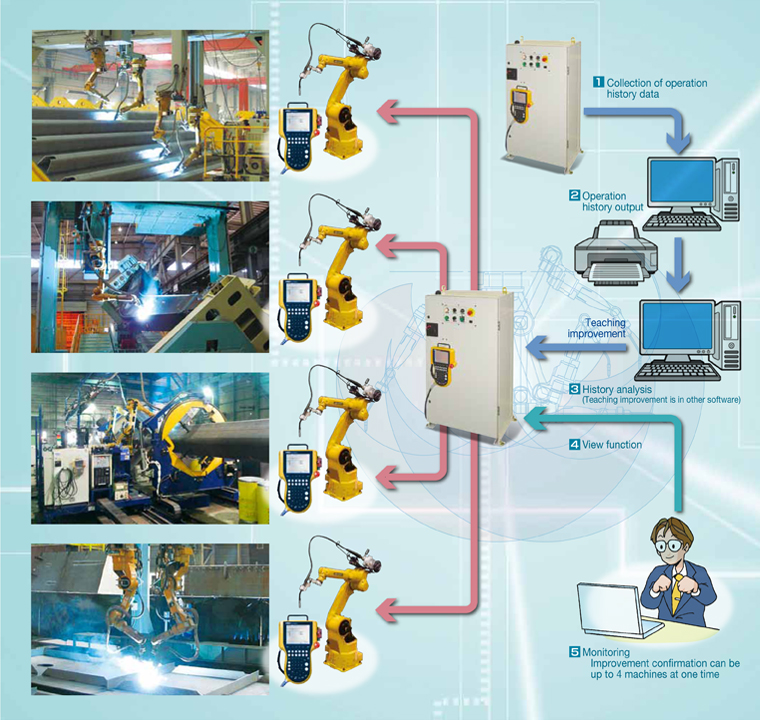

Production Support System

Overview of operation history and monitoring

- Collection of operation history data

ARCMANTM operation history is automatically saved to the controller. This software automatically retrieves the data. - Operation history output

From this data, this software creates monthly reports of operational performance, incorporating tabularization and graphs.

This data can divided by manipulator, task, etc., as well as by specified period such as day, week, or month. - Operational record analysis support

The data contains information including instructions, any issues, operations performed to address said issues, and more.

This software facilitates analysis, contributing to improved productivity. - View function (optional)

The software contributes to the improvement process.

It can monitor multiple ARCMANTMs at once.

Overview of operation history and monitoring

- Collection of operation history data

- ARCMANTM operation history is automatically saved to the controller.

Operational records of ARCMANTM are constantly saved automatically.

However, if capacity is exceeded, data is over-written and saved. - This software automatically retrieves the data.

Where this software is downloaded on PCs linked to controllers, this data is automatically retrieved from ARCMANTM.

- ARCMANTM operation history is automatically saved to the controller.

- Operation history output

- From this data, this software creates monthly reports of operational performance, incorporating tabularization and graphs.

This software creates monthly operation performance reports from the data received at the beginning of each month.

The reports include tabularization, graphs, etc., to help clarify operational circumstances and any issues on a monthly basis. - This data can divided by manipulator, task, etc., as well as by specified period such as day, week, or month.

The monthly report provides a benchmark. This data can be divided by the customer by manipulator, task, etc., as well as by specified period such as day, week, or month.

- From this data, this software creates monthly reports of operational performance, incorporating tabularization and graphs.

- Operational record analysis support

- The data contains information including instructions, any issues, operations performed to address said issues, and more. Retrieved data contains all information including instructions, tracked changes, any issues, operations performed to address said issues, and more.

- This software facilitates analysis, contributing to improved productivity.

This software records and stores operation history information, helping the customer to perform their own analysis. This facilitates better productivity of ARCMANTM.

- View function (optional)

- PCs equipped with this software are capable of live operation monitoring through networks, regardless of distance.

Software operating conditions and options

Off-line Teaching System

| PC | Desktop or notebook PC |

|---|---|

| OS | Windows 7 Professional 32-bit version (64-bit version works with 32-bit compatibility mode) |

| Not supported by Windows 8 | |

| CPU | Pentium (2GHz or greater) 1CPU |

| Memory | 2 GB or greater (where data is large, more memory is recommended) |

| HDD | 10 GB or greater (free space) |

| USB slot | Two or more (one exclusively for bootup) |

| LAN port | Cable LAN |

| Other | DIRECT X required |

| Monitor resolution 1280 x 1024 or higher | |

| Notes | Where the software does not operate properly due to problems with security software, please stop operations or delete. |

Production Support System

| PC | Desktop or notebook PC |

|---|---|

| OS | Windows 7 Professional 32-bit version (64-bit version works with 32-bit compatibility mode) |

| Not supported by Windows 8 | |

| CPU | Pentium (2GHz or greater) 1CPU |

| Memory | 2 GB or greater |

| HDD | 10 GB or greater (free space) |

| USB slot | Two or more (When using the View function, use one additional ) LAN exclusively for this purpose. |

| LAN port | Cable LAN |

| Other | Microsoft Excel and a robot LAN manufactured by our company are required. |

| Monitor resolution 1280 x 1024 or higher | |

| Notes | Where the software does not operate properly due to problems with security software, please stop operations or delete. |

Software education and training

Off-line Teaching System

- Training location / prerequisite regarding target audience

In general, instructions on operations and other training on this software are held at our Fujisawa location.

Robot operations require safety and robot operations training as specified under the law. Prior to taking this software operations course, you must first take safety training as well as ARCMANTM training. - Curriculum Overview

Program Schedule Items Important Study Points Day 1 AM Flow of operations / basic mouse operations / view operations / parts model compilation Trainees learn flow of operations of this software for standard layouts, and basic operations. Day 1 AM Task model and layout creation / instructions Replay simulation / databank compilation Day 2 AM CADCN data conversation,

layout positioning / save / Path creationNotes on input / output; specification of torch angle, slider position, and databanks Day 2 AM Data management / program structuring PRG compilation function / calibration Installation / data send & receive PRG shift, mirror conversion, pasting, program revision

Send / receive PRG / DBK

Production Support System

- Training location / prerequisite regarding target audience

In general, operations training for this software is held on customer premises.

Understanding of basic Microsoft Windows operations is a prerequisite.- Microsoft and Windows are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or other countries.

- Operations training

Program Schedule Items Approximately one hour Operations are explained using the software manual.

Products

- Main Products

- Welding Consumables

- Arc welding robots

- Industries - Recommended Materials

- Welding Handbook Quick View

- Product Quick View & Highlights

- For HEAT-RESISTANT STEEL

- For STAINLESS STEEL

- For LOW-TEMPERATURE STEEL

- Product Highlight

- Catalog

- Technical Highlights

- Certification

- SDS ※English Only

- ARCMAN

- Welding Robot

- Software