Industries - Recommended Materials

- Pressure Vessels

- Off-shore Structures

- LNG

Storage Tanks - Ship Building

- Automobile

- Bridges

- Building Structure

Pressure Vessels

Heat resistant steel that includes Chromium (Cr) and Molybdenum (Mo) is used in order to guarantee strength and toughness in the pressure vessels used in the synthesis of various chemicals in a high temperature, high pressure environment and in power generation etc. The same composition is required in welding materials, and we have developed various such materials to meet the characteristics of each steel material and demand.

Welding Consumables for Pressure Vessels

| Steel type | Welding Method |

Welding Consumables |

ASME/AWS | Polarity | Flux grain size (mesh) diameter(mmø) |

|---|---|---|---|---|---|

| 1.25Cr-0.5Mo steel ASTM A387 Gr.11 Cl.1 & Cl.2 |

SAW (Flux/Wire) |

PF-200/US-511N | SFA/A 5.23 F8P2-EG-B2 |

AC | Flux:10×48 3.2, 4.0 |

| SMAW | CM-A96MB | SFA/A 5.5 E8016-B2 |

AC | 2.6, 3.2 4.0, 5.0 |

|

| GTAW | TG-S1CM | SFA/A 5.28 ER80S-G |

DCEN | 1.2, 1.6 2.0, 2.4 |

|

| 2.25Cr-1Mo steel ASTM A387 Gr.22 Cl.1 & Cl.2 |

SAW (Flux/Wire) |

PF-200/US-521S | SFA/A 5.23 F9P2-EG-B3 |

AC | Flux:10×48 3.2, 4.0 |

| SMAW | CM-A106N | SFA/A 5.5 E9016-B3 |

AC | 2.6, 3.2 4.0, 5.0 |

|

| GTAW | TG-S2CM | SFA/A 5.28 ER90S-G |

DCEN | 1.2, 1.6 2.0, 2.4 |

|

| 2.25Cr-1Mo-V steel ASTM A387 Gr_22V |

SAW (Flux/Wire) |

PF-500/US-521H | SFA/A 5.23 F9P2-EG-G | AC | Flux:10×48 3.2, 4.0 |

| SMAW | CM-A106H | SFA/A 5.5 E9016-G | AC | 3.2, 4.0 5.0 |

|

| GTAW | TG-S2CMH | SFA/A 5.28 ER90S-G | DCEN | 1.2, 1.6 2.0, 2.4 |

| Welding consumables | C | Si | Mn | P | S | Cr | Mo | Nb | V |

|---|---|---|---|---|---|---|---|---|---|

| PF-200/US-511N | 0.09 | 0.10 | 0.74 | 0.006 | 0.005 | 1.43 | 0.54 | ― | ― |

| CM-A96MB | 0.06 | 0.51 | 0.74 | 0.007 | 0.003 | 1.30 | 0.54 | ― | ― |

| TG-S1CM | 0.06 | 0.45 | 0.98 | 0.007 | 0.006 | 1.22 | 0.54 | ― | ― |

| PF-200/US-521S | 0.11 | 0.10 | 0.85 | 0.006 | 0.005 | 2.34 | 1.04 | ― | ― |

| CM-A106N | 0.11 | 0.33 | 0.81 | 0.005 | 0.002 | 2.28 | 0.98 | ― | ― |

| TG-S2CM | 0.09 | 0.32 | 0.71 | 0.007 | 0.006 | 2.26 | 1.04 | ― | ― |

| PF-500/US-521H | 0.08 | 0.13 | 1.16 | 0.004 | 0.004 | 2.53 | 1.03 | 0.015 | 0.35 |

| CM-A106H | 0.08 | 0.31 | 1.18 | 0.004 | 0.002 | 2.42 | 1.01 | 0.017 | 0.29 |

| TG-S2CMH | 0.10 | 0.14 | 0.42 | 0.005 | 0.006 | 2.30 | 1.04 | 0.034 | 0.28 |

| Welding consumables | PWHT | 0.2%Y.S. MPa |

T.S. MPa |

El. % |

vE J |

|---|---|---|---|---|---|

| PF-200/US-511N | 690 ℃×4hr | 480 | 605 | 29 | 120(-18℃) |

| CM-A96MB | 690 ℃×1hr | 490 | 590 | 30 | 180(-18℃) |

| TG-S1CM | 690 ℃×1hr | 540 | 630 | 28 | 270(0℃) |

| PF-200/US-521S | 690 ℃×8hr | 470 | 610 | 27 | 150(-29℃) |

| CM-A106N | 690 ℃×8hr | 510 | 650 | 28 | 125(-40℃) |

| TG-S2CM | 690 ℃×1hr | 610 | 720 | 28 | 250(0℃) |

| PF-500/US-521H | 705 ℃×7hr | 620 | 710 | 26 | 120(-18℃) |

| CM-A106H | 705 ℃×7hr | 610 | 710 | 23 | 150(-18℃) |

| TG-S2CMH | 705℃×7hr | 623 | 718 | 22 | 240(-18℃) |

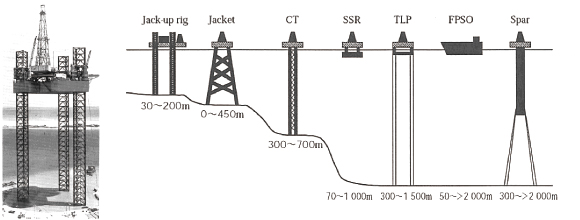

Off-shore Structures

Various offshore structures are constructed at underwater oilfields to match the environment and the depth of the development. A strength and toughness suited to the ocean environment is necessary, and a high strength and excellent low temperature toughness are required in the structural steel and welding materials used.

Types of offshore structures and their working water depth

Welding Consumables for Off-shore structures

| Tensile strength(MPa) | ≧490 | ≧520 | ≧550 | ≧610 | ≧670 | ≧770 | |

|---|---|---|---|---|---|---|---|

| Yield strength(MPa) | ≧350 | ≧400 | ≧420 | ≧500 | ≧550 | ≧690 | |

| Absorbed energy(J) | ≧35 | ≧40 | ≧42 | ≧50 | ≧55 | ≧69 | |

| Service temperature (℃) |

-20 | LB-52 (AC/DCEP) [AW/SR] LB-52A (AC/DCEP) [AW/SR] LB-52-18 (AC/DCEP) [AW] |

LB-57 (AC/DCEP) [AW/SR※] |

LB-62UL (AC/DCEP) [AW/SR] LB-62 (AC/DCEP) [AW/SR] LB-62U (AC/DCEP) [AW/SR] |

LB-106 (AC/DCEP) [AW] |

LB-116 (AC/DCEP) [AW] LB-80UL (AC) [AW] |

|

| -40 | LB-7018-1 (DCEP) [AW] LB-52U (AC/DCEP) [AW/SR※] |

NB-1SJ (AC/DCEP) [AW/SR] LB-52NS (AC) [AW] |

NB-1SJ (AC) [AW/SR] LB-62L (AC/DCEP) [AW/SR] |

LB-62L (AC) [AW/SR] LB-65L (DCEP) [AW/SR] LB-67L (DCEP) [AW/SR] |

LB-70L (DCEP) [AW] |

LB-88LT (AC) [AW] LB-80L (DCEP) [AW] |

|

| -60 | NB-1SJ (AC/DCEP) [AW/SR] LB-52NS (AC/DCEP) [AW/SR] |

LB-Y75 (AC) [AW] |

|||||

※ SR:AC only

| Tensile strength(MPa) | ≧490 | ≧520 | ≧550 | ≧610 | ≧670 | ≧770 | |

|---|---|---|---|---|---|---|---|

| Yield strength(MPa) | ≧350 | ≧400 | ≧420 | ≧500 | ≧550 | ≧690 | |

| Absorbed energy(J) | ≧35 | ≧40 | ≧42 | ≧50 | ≧55 | ≧69 | |

| Service temperature (℃) |

-20 | MF-38/US-49A (AC) [AW/SR] |

MF-38/ US-40 (AC) [AW] |

PF-H80AK/ US-255 (AC) [AW] PF-H80AS/ US-255 (DCEP) [AW] |

PF-H80AS/ US-80LT (DCEP) [AW] PF-H80AK/ US-80LT (AC) [AW] |

||

| -40 | PF-H55AS/ US-36J (DCEP) [AW/SR] PF-H55LT/ US-36 (DCEP) [AW/SR] |

PF-H55S/US-49A (AC) [AW/SR] |

PF-H55S/US-49A (AC) [AW/SR] PF-H80AK/US-56B (DCEP) [AW] |

PF-H55S/ US-40 (AC) [AW] PF-H80AK/ US-56B (AC/DCEP) [AW] |

|||

| -60 | PF-H55AS/US-36J (DCEP) [AW] PF-H55LT/US-36 (AC) [AW] PF-H55LT/US-36J (AC) [AW/SR] |

PF-H55LT/US-36J (AC) [AW] |

PF-H80AK/ US-56B (AC) [AW/SR] PF-H55S/ US-2N (AC) [AW/SR] PF-H62AS/ US-2N (DCEP) [AW] |

PF-H80AK/ US-255 (AC) [AW] |

|||

| Tensile strength(MPa) | ≧490 | ≧520 | ≧550 | ≧610 | ≧670 | ≧770 | |

|---|---|---|---|---|---|---|---|

| Yield strength(MPa) | ≧350 | ≧400 | ≧420 | ≧500 | ≧550 | ≧690 | |

| Absorbed energy(J) | ≧35 | ≧40 | ≧42 | ≧50 | ≧55 | ≧69 | |

| Service temperature (℃) |

-20 | DW-50 (100%CO2) [AW] DW-A50 (Ar+20%CO2) [AW] MG-S50 (Ar+20%CO2) [AW/SR] |

DW-55L (100%CO2) [AW] MG-T1NS (Ar+20%CO2) [AW] DW-A81Ni1 (Ar+20%CO2) [AW] DW-A62LSR (Ar+20%CO2) [AW/SR] |

DW-A65L (Ar+20%CO2) [AW] MG-T1NS (Ar+20%CO2) [AW] |

MG-S70 (Ar+20%CO2) [AW] |

MG-S80 (Ar+20%CO2) [AW] |

|

| -30 | DW-55E (100%CO2) [AW] DW-A55E (Ar+20%CO2) [AW] DW-A55ESR (Ar+20%CO2) [AW/SR] |

||||||

| -40 | DW-67E (CO2) [AW] |

DW-A80L (Ar+20%CO2) [AW] |

|||||

| -50 | DW-50LSR (100%CO2) [AW/SR] |

DW-55LSR (100%CO2) [AW/SR] DW-A55L (Ar+20%CO2) [AW] DW-A55LSR (Ar+20%CO2) [AW/SR] MG-S50LT (Ar+20%CO2) [AW] MX-A55T (Ar+20%CO2) [AW] |

DW-A81Ni1 (Ar+20%CO2) [AW] |

DW-62L (100%CO2) [AW] DW-A62L (Ar+20%CO2) [AW] DW-S62L (Ar+20%CO2) [AW] DW-A62LSR (Ar+20%CO2) [AW] |

- | MG-S88A (Ar+20%CO2) [AW] MX-A80L (Ar+20%CO2) [AW] |

|

| -60 | DW-55L (100%CO2) [AW] DW-A55L (Ar+20%CO2) [AW] MG-S50LT (Ar+20%CO2) [AW/SR] MX-A55T (Ar+20%CO2) [AW] |

DW-55LSR (100%CO2) [AW] DW-A55L (Ar+20%CO2) [AW] DW-A55LSR (Ar+20%CO2) [AW] MX-A55T (Ar+20%CO2) [AW] |

|||||

| Tensile strength(MPa) | ≧490 | ≧520 | ≧550 | ≧610 | ≧670 | ≧770 | |

|---|---|---|---|---|---|---|---|

| Yield strength(MPa) | ≧350 | ≧400 | ≧420 | ≧500 | ≧550 | ≧690 | |

| Absorbed energy(J) | ≧35 | ≧40 | ≧42 | ≧50 | ≧55 | ≧69 | |

| Service temperature (℃) |

-20 | TG-S50 [AW/SR] TG-S51T [AW/SR] |

TG-S62 [AW/SR] TG-S60A [AW/SR] |

TG-S80AM [AW/SR] |

|||

| -40 | TG-S1MT [AW] TG-S1N [AW] |

TG-S60A [AW/SR] |

|||||

| -60 | |||||||

Click here for the details of each product.

KOBELCO WELDING TODAY Special Edition

Click here for our latest technology

LNG Storage Tanks

Liquefied natural gas (LNG) is widely used as a fuel with a low environmental impact. 9% nickel steel, which has good toughness at very low temperatures, is used in the steel tanks that liquefy and store LNG. A ratio of 9% nickel, equivalent to that of steel material, does not satisfy the requirements made of the welding material, for which a material containing almost 70% nickel is used.

Welding Consumables for LNG Storage Tanks

| Steel type | Welding Method |

Welding Consumables |

ASME/AWS | Polarity | Flux grain size(mesh) diameter(mmø) |

Example of application section |

|---|---|---|---|---|---|---|

| 9%Ni steel JIS G3127 SL9N590 ASTM A533 Type 1 |

SAW (Flux/Wire) |

PF-N4/ US-709S |

SFA/A 5.14 ERNiMo-8 (US-709S) |

DCEP | Flux:12×65 2.4 |

Side plate (Horizontal) |

| SMAW | Ni-C70S | SFA/A 5.11 ERNiCrFe-9 |

AC | 3.2, 4.0, 5.0 | Side plate (Vertical, Horizontal) Bottom plate |

|

| Ni-C1S | SFA/A 5.11 ERNiMo-8 |

Tack and Repair welding |

||||

| GTAW | TG-S709S | SFA/A 5.14 ERNiMo-8 |

DCEN | 1.2, 1.6 2.0, 2.4 |

Side plate, Bottom plate, Tack and Repair welding, etc. |

|

| FCAW | DW-N709SP | SFA/A 5.34 ENiMo13T1-1,1-4 |

DCEP | 1.2 | Roof, Jig, etc Side plate(Vertial), etc,Bottom plate |

|

| Mild steel JIS G3106 SM490 ASTM A36 |

SMAW | LB-52A | SFA/A 5.1 E7016 |

AC/ DCEP |

2.6, 3.2, 4.0 5.0, 6.0 |

Outer tank |

| GTAW | TG-S50 | SFA/A 5.18 ER70S-G |

DCEP | 1.2, 1.6, 2.0 2.4, 3.2 |

Outer tank | |

| 304type stainless steel JIS G4304 SUS304L ASTM A167 Type 304L |

SMAW | NC-38LT | SFA/A 5.4 E308L-16 |

AC/ DCEP |

2.6, 3.2, 4.0 | Pipe |

| GTAW | TG-S308L | SFA/A 5.9 ER308L |

DCEP | 1.0, 1.2, 1.6 2.0, 2.4, 3.2 |

Pipe | |

| FCAW | DW-308LP | SFA/A 5.22 E308LT1-1/4 |

DCEN | 1.2 | Pipe |

| Welding consumables | C | Si | Mn | P | S | Ni | Cr | Mo | Fe | Nb | W |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PF-N4/US-709S | 0.02 | 0.61 | 0.30 | 0.002 | 0.001 | 67.1 | 1.8 | 18.6 | 8.3 | ― | 2.9 |

| NI-C70S ※ | 0.09 | 0.23 | 2.20 | 0.003 | 0.002 | 65.0 | 16.5 | 4.9 | 9.8 | 1.2 | 0.6 |

| NI-C1S ※ | 0.03 | 0.49 | 0.30 | 0.003 | 0.002 | 68.6 | 1.9 | 18.6 | 6.8 | ― | 2.9 |

| TG-S709S | 0.02 | 0.03 | 0.03 | 0.002 | 0.001 | 70.4 | 2.0 | 19.0 | 5.5 | ― | 3.0 |

| DW-N709SP | 0.02 | 0.21 | 2.75 | 0.003 | 0.002 | 62.1 | 6.9 | 17.6 | 7.7 | ― | ― |

| LB-52A ※ | 0.08 | 0.57 | 1.12 | 0.012 | 0.005 | ― | ― | ― | ― | ― | ― |

| TG-S50 | 0.09 | 0.73 | 1.35 | 0.009 | 0.010 | ― | ― | ― | ― | ― | ― |

| NC-38LT ※ | 0.03 | 0.38 | 2.12 | 0.022 | 0.002 | 10.9 | 18.4 | ― | ― | ― | ― |

| TG-S308L | 0.02 | 0.48 | 1.98 | 0.023 | 0.003 | 9.7 | 19.9 | ― | ― | ― | ― |

| DW-308LP | 0.03 | 0.71 | 1.18 | 0.023 | 0.009 | 9.5 | 20.4 | ― | ― | ― | ― |

| Welding consumables | 0.2%Y.S. MPa |

T.S. MPa |

EI. % |

vE-196℃ J |

|---|---|---|---|---|

| PF-N4/US-709S | 435 | 716 | 48 | 88 |

| NI-C70S ※ | 450 | 710 | 41 | 67 |

| NI-C1S ※ | 440 | 730 | 48 | 83 |

| TG-S709S | 460 | 730 | 47 | 160 |

| DW-N709SP | 450 | 710 | 46 | 90 |

| LB-52A ※ | 500 | 580 | 31 | 230(0℃) |

| TG-S50 | 480 | 580 | 31 | 180(-30℃) |

| NC-38LT ※ | 370 | 540 | 51 | 51 |

| TG-S308L | 420 | 590 | 45 | 78 |

| DW-308LP | 420 | 630 | 40 | 35 |

※ AC only

Check TECHNICAL HIGHLIGHTVol.2 & 15 for welding of 9%Ni steel of LNG tanks.

Click here for DW-N609SV, FCAW for fuel tanks on LNG-powered ship.

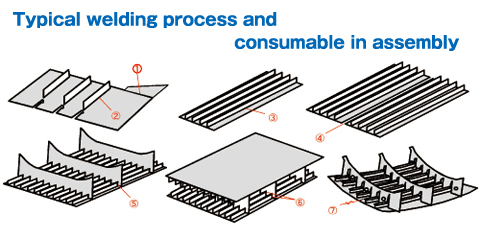

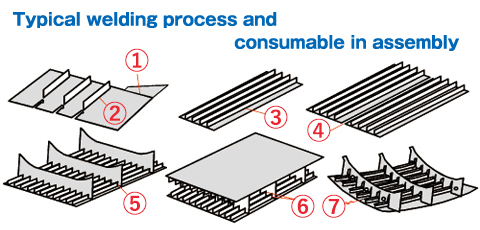

Ship Building

The majority of goods traded in intercontinental commerce are transported by sea. The ships used in marine transport are impacted by weather conditions and can be exposed to dynamic stress due to high winds and waves. Whilst size is restricted by passages such as the Suez Canal and the Panama Canal, the loading capacity of ships continues to increase and excellent design and materials are employed to provide a strength and toughness that ensures safe shipping. Various high-efficiency construction methods that use the most welding material in proportion to the quantity of steel are employed to reduce the construction period.

Welding Consumables for Shipbuilding

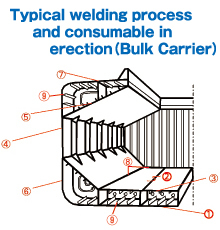

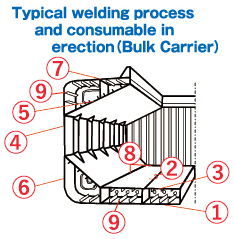

※click numbers for more information

TRIFARC™ Method(High Speed Triple Tandem One Pool Method)& RF™ Process

(1)

| Production | Type of members and joints |

Welding position |

Welding process | Typical welding consumables | Remarks. | |

|---|---|---|---|---|---|---|

| D grade | E grade | |||||

| Sub-Assembly | Flat panel/butt | Flat | Both side SAW | US-36/ PF-H55E | Automatic | |

(2)

| Production | Type of members and joints |

Welding position |

Welding process | Typical welding consumables | Remarks. | |

|---|---|---|---|---|---|---|

| D grade | E grade | |||||

| Sub-Assembly | Stiffener/Fillet | Horizontal | GMAW | MX-200 DW-200 |

MX-200E DW-200 |

Single arc DW-200 for legth length 8 to 10mm |

(3)

| Production | Type of members and joints |

Welding position |

Welding process | Typical welding consumables | Remarks. | |

|---|---|---|---|---|---|---|

| D grade | E grade | |||||

| Assembly | Longi./Fillet | Horizontal | GMAW | MX-200 MX-200H MX-200HS |

MX-200E MX-200H MX-200HS |

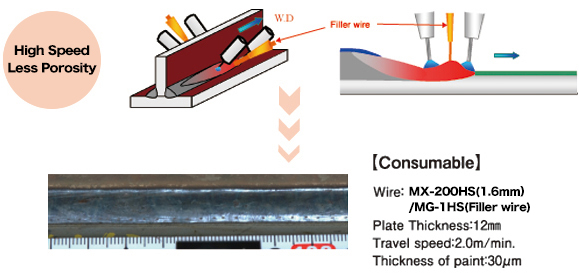

MX-200H:Twin tandem one pool MX-200HS:TRIFARC™ |

(4)

| Production | Type of members and joints |

Welding position |

Welding process | Typical welding consumables | Remarks. | |

|---|---|---|---|---|---|---|

| D grade | E grade | |||||

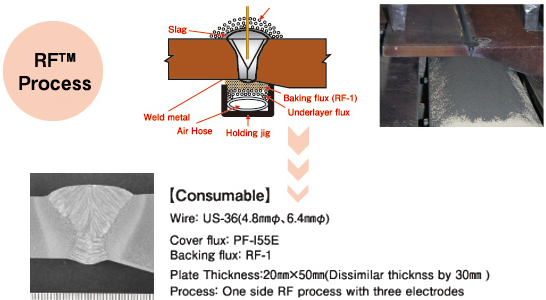

| Assembly | Panel plate/butt | Flat | One side SAW | US-36/ PF-I55E/ PF-I50R US-36/ PF-I55E/ RF-1 |

(FCB™/RF™) | |

(5)

| Production | Type of members and joints |

Welding position |

Welding process | Typical welding consumables | Remarks. | |

|---|---|---|---|---|---|---|

| D grade | E grade | |||||

| Assembly | Slot trans./Fillet | Horizontal Vertical | GMAW | DW-100V | DW-55E | Robotic |

(6)

| Production | Type of members and joints |

Welding position |

Welding process | Typical welding consumables | Remarks. | |

|---|---|---|---|---|---|---|

| D grade | E grade | |||||

| Assembly | Inner double hull/Fillet | Horizontal Vertical | GMAW | DW-100 | DW-55E | Semi-automatic |

(7)

| Production | Type of members and joints |

Welding position |

Welding process | Typical welding consumables | Remarks. | |

|---|---|---|---|---|---|---|

| D grade | E grade | |||||

| Assembly | Bilge shell/butt | Flat | One side SAW | US-36/ PF-I52E/ RR-2/ FA-B1 | (FAB) | |

| One side GMAW | DW-100/ FB-B3 | DW-55E FB-B3 | Semi-automatic | |||

(1)

| Type of members and joints |

Welding position |

Welding process |

Typical welding consumables | Remarks. | |

|---|---|---|---|---|---|

| D grade | E grade | ||||

| Bottom shell/Butt | Flat | One side GMAW | DW-100/ FB-B3 | DW-55E/ FB-B3 | Semi-automatic |

(2)

| Type of members and joints |

Welding position |

Welding process |

Typical welding consumables | Remarks. | |

|---|---|---|---|---|---|

| D grade | E grade | ||||

| Tank top (Long.)/Butt | Flat | One side SAW | US-36/ PF-I52E/ RR-2/ FA-B1 | (FAB) | |

| One side GMAW | MG-50D/ FB-B3 | Automatic(MAG) | |||

(3)

| Type of members and joints |

Welding position |

Welding process |

Typical welding consumables | Remarks. | |

|---|---|---|---|---|---|

| D grade | E grade | ||||

| Tank top (Trans.)/Butt | Flat | One side GMAW + SAW |

DW-100/ FB-B3 +US-36/ PF-H55E |

DW-55E/ FB-B3 +US-36/ PF-H55E |

Semi-automatic +Automatic |

(4)

| Type of members and joints |

Welding position |

Welding process |

Typical welding consumables | Remarks. | |

|---|---|---|---|---|---|

| D grade | E grade | ||||

| Side shell/Butt | Vertical | Electrogas | DW-S43G/ KL-4, DW-S1LG/ KL-4 | Automatic(SEGARC™) | |

| DW-100V | DW-55E | Semi-automatic | |||

(5)

| Type of members and joints |

Welding position |

Welding process |

Typical welding consumables | Remarks. | |

|---|---|---|---|---|---|

| D grade | E grade | ||||

| Top side tank/Butt | Flat | One side GMAW | DW-100/ FB-B3 | DW-55E/ FB-B3 | Semi-automatic |

(6)

| Type of members and joints |

Welding position |

Welding process |

Typical welding consumables | Remarks. | |

|---|---|---|---|---|---|

| D grade | E grade | ||||

| Bilge hopper/Butt | Horizontal Vertical |

One side GWAW | DW-100/ FB-B3 DW-100V/ FB-B3 |

DW-55E/ FB-B3 | Semi-automatic |

(7)

| Type of members and joints |

Welding position |

Welding process |

Typical welding consumables | Remarks. | |

|---|---|---|---|---|---|

| D grade | E grade | ||||

| Upper deck/Butt | Flat | One side GMAW + SAW |

DW-100/ FB-B3 +US-36/ PF-H55E |

DW-55E/ FB-B3 +US-36/ PF-H55E |

(FAB) |

| Automatic(MAG) | |||||

(8)

| Type of members and joints |

Welding position |

Welding process |

Typical welding consumables | Remarks. | |

|---|---|---|---|---|---|

| D grade | E grade | ||||

| Tank top/Fillet | Horizontal | GMAW | MX-200 | MX-200E | Simple mechanical |

(9)

| Type of members and joints |

Welding position |

Welding process |

Typical welding consumables | Remarks. | |

|---|---|---|---|---|---|

| D grade | E grade | ||||

| Long./Fillet | Flat Vertical | One side GMAW | DW-100/ FB-B3 | DW-55E/ FB-B3 | Semi-automatic |

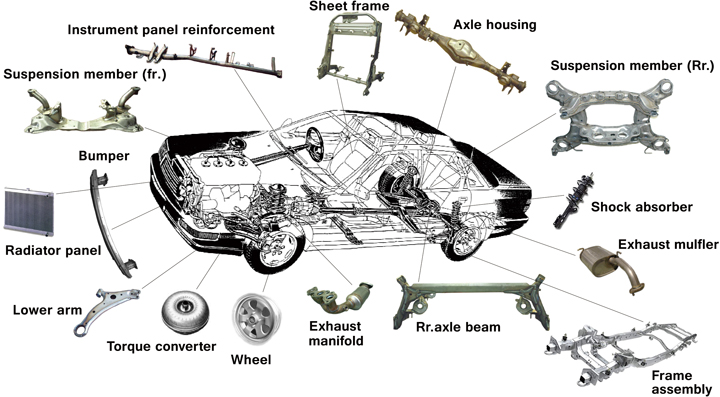

Automobile

The development of lightweight, fuel efficient cars and electric vehicles that do not use fossil fuels and the outfitting of an EV infrastructure are progressing. Whilst the usage ratio of steel material is decreasing, a reduction in weight by increased strength and improvement of fatigue strength is being explored.

Welding Consumables for Automobile

Example of typical automobile assembly that the arc welding is applied.

※click automobile parts for more information

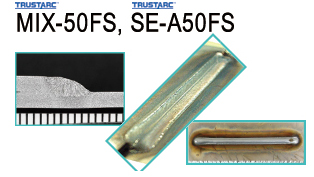

Viscosity of molten weld metal

| Surface type | large ← Viscosity → Lower | ||

|---|---|---|---|

| Cu-coated | MIX-1TS | MIX-50 | MIX-50FS |

| SE(non-Cu) | SE-A1TS | SE-A50 | SE-A50FS |

| Recommned | Galvanized steel, Downhill | General purpose | Flat, horizontal |

New concept wires

FAMILIARC™ MIX-1TR: Solid wire to improve electroposition coating property

・It provides the weld with improved electroposition coating properties with the existing equipment.

・Undercut is not likely to occur at the toe of the welded bead even in the welding of sheets with gaps.

・Bead configuration is not likely to become convex even in highspeed welding.

・Stable welding with little spatter is possible by selecting optimum welding parameters.

| Wire | Before electrodeposition coating | After electrodeposition coating | ||||||

|---|---|---|---|---|---|---|---|---|

| [F] MIX-1TR |  |

|

||||||

| Conv.wire (Conventional wire) |  |

|

||||||

|

||||||||

Fig: Bead appearance comparison before and after electrodeposition coating between MIX-1TR and a conventional solid wire

New concept wires that have excellent bead appearance, shape, paint-ability

For more information, click here for Technical Highlight Vol. 12, 28 & 31.

Vol.12: Advanced MAG and MIG Welding Wires : Meeting Car Manufacturing Requirements for Fast and Efficient Welding

Vol.28: Solid wires for thin steel sheets:TRUSTARC™ MG-S120T for ultra-high tensile strength and,FAMILIARC™ MG-1T(F) for wire feeding control

Vol.31: FAMILIARC™ MIX-1TR: the solid wire for GMAW to improve electrodeposition coating property

・Frame ・Lower arm ・Axle beam ・Axle housing ・torque converter

| Type of steel and thickness | Welding method | Recommened brand | wire dia. |

|---|---|---|---|

| Carbon steel 2.3~4.0mm |

CO2 | SE-50T, MG-50T, MG-51T | 1.2mm |

| MAG Pulsed-MAG |

SE-A50, MIX-50 SE-A50S MIX-50FS |

・Impact beam ・Bumper

| Type of steel and thickness | Welding method | Recommened brand | Wire dia. |

|---|---|---|---|

| Carbon steel sheet and pipe 1.4~2.3mm |

CO2 | SE-50T, MG-50T, MG-51T | 1.2mm |

| MAG Pulsed-MAG |

SE-50T, MIX-50 |

・Suspension member

| Type of steel and thickness | Welding method | Recommened brand | wire dia. |

|---|---|---|---|

| Carbon steel 1.6~2.6mm |

CO2 | SE-50T, MG-50T, MG-51T | 1.2mm |

| MAG Pulsed-MAG |

SE-A50, MIX-50 MIX-50FS |

||

| Galvanized steel 1.6~2.6mm |

CO2 | SE-50T, MG-1Z MX-100Z |

1.2mm |

| Pulsed-MAG | SE-A1TS, MIX-1TS MIX-1Z |

||

| Anti-corrosion steel 1.6~2.6mm | Pulsed-MAG | SE-A1TS, MIX-1TS |

・Instrument panel reinforcement ・Sheet frame

| Type of steel and thickness | Welding method | Recommened brand | wire dia. |

|---|---|---|---|

| Carbon steel 0.8~1.6mm |

CO2 | SE-50T, MG-50T, MG-51T | 0.8~1.0mm |

| MAG | SE-A50, MIX-50 | ||

| MAG +Variable porarity power souce |

MG-1SP | 1.2mm |

・Exhaust musffler ・Exhaust manifold

| Type of steel and thickness | Welding method | Recommened brand | wire dia. |

|---|---|---|---|

| Stainless steel 0.8~2mm |

MAG | MX-A430(Ferritic) | 1.2mm |

| Pulsed-MIG | MG-S308(Austenitic) MG-S309(Austenitic) |

1.2mm |

・Radiator panel ・Alminum wheel

| Type of steel and thickness | Welding method | Recommened brand | wire dia. |

|---|---|---|---|

| Aluminum alloy | TIG | A-403BY | 1.2mm |

| MIG | A-4040WY | 1.2mm | |

| MIG | A-4043WY, A-5356WY | 1.2mm | |

| MIG | A-5356WY | 1.2mm | |

| MIG | A-5183WY, A-5356WY | 1.2mm |

Bridges

This page has been deleted because the information is out of date

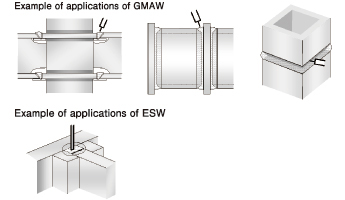

Building Structure

Example of applications

Welding Consumables for Building Structures

| Steel1) | Strength class1) | Welding method | JIS classification | Brand name of welding consumable |

|

|---|---|---|---|---|---|

| Carbon steel |

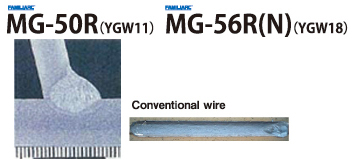

400,490MPa | GMAW2) | CO2 semi-auto | Z3312 YGW11 | MG-50 |

| CO2 robot | Z3312 YGW11 | MG-50R | |||

| Ar+CO2 robot | Z3312 YGW15 | MG-50R | |||

| 400,490MPa 520,550MPa |

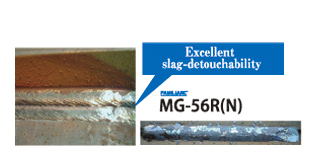

CO2 semi-auto | Z3312 YGW18 | MG-56 | ||

| CO2 robot | MG-56R(N) | ||||

| Ar+CO2 robot | Z3312 YGW19 | MIX-55R | |||

| 400,490,520MPa | Sub-merged arc (SAW) | Z3313 S502-H | US-36L / PF-I53ES | ||

| High tensile steel |

570,590MPa | GMAW2) | CO2 | Z3312 G59JA1UC3M1T | MG-60 |

| Ar+CO2 | Z3312 G59JA1UMCM1T | MG-S63B | |||

| Sub-merged arc (SAW) | Z3313 S502-H | US-49 / PF-I55ES | |||

| 690MPa | GMAW2) | CO2 | Z3312 G69A2UCN2M4T | MG-70 | |

| 780MPa | CO2 | Z3312 G78A2UCN4M4T | MG-80 | ||

| Fire -resistant steel |

400MPa | GMAW2) | CO2 | Z3312 G43A0UC11 | MG-400FR |

| 400,490,520MPa | GMAW2) | CO2 | Z3312 G49A0UC3M1T | MG-490FR | |

| Sub-merged arc (SAW) | Z3183 S502-H | US-400LFR / PF-I53ES | |||

※2):Solid wire (Flux-cored wires is prepared elsewhere,too)

| Kind, class | JIS and the sign name of steel of the object |

|---|---|

| 400MPa | SN400,SM400,SS400,STKN400,STKR400 BCP235,BCR295 |

| 490MPa | SN490,SM490,TMC325,STKN490,STKR490 BCP325,BCP325T |

| 520MPa | SM520,TMC355 |

| 550MPa | TMC385 |

| 570MPa | SM570 |

| 590MPa | SA440 |

| Fire-resistant | SM400-FR,SM490-FR,SM520-FR |

Solid wires suitable for building structure welding robots

Click here for the details of these products.(English only)

Visit our YouTube Channel for ARCMAN™ welding robot system.

Products

- Main Products

- Welding Consumables

- Arc welding robots

- Industries - Recommended Materials

- Welding Handbook Quick View

- Product Quick View & Highlights

- For HEAT-RESISTANT STEEL

- For STAINLESS STEEL

- For LOW-TEMPERATURE STEEL

- Product Highlight

- Catalog

- Technical Highlights

- Certification

- SDS ※English Only

- ARCMAN

- Welding Robot

- Software