- Home >

- Products >

- Product Highlight >

- FAMILIARC™ OW-S50P(E71T-8-H16):Self-shielded flux cored wire for overseas market >

Products Spotlight

FAMILIARC™ OW-S50P(E71T-8-H16):Self-shielded flux cored wire for overseas market

The current line-up of self-shielded flux cored wires (self-shielded FCWs) include [F]OW-S50H, used in on-site welding of steel pipe piles in the flat and horizontal positions, and [F]OW-S50T, which is suitable for welding thin plates with thickness of 1.0 to 4.5 mm. They are highly reputed but marketed in Japan only. However, as the pursuit of high welding efficiency becomes a rising global trend, [F]OW-S50P, a self-shielded FCW matching AWS A5.20 E71T-8-H16 has been developed in order to target overseas markets. Table 1 shows KOBELCO ’ s line-up of self-shielded FCWs.

| Welding position | Specification | |

|---|---|---|

| [F]OW-S50P | All | AWS A5.20 E71T-8-H16 EN ISO 17632-B T 49 3 T8-1 NO A |

| [F]OW-S50H | 1F, 1G, 2F and 2G | AWS A5.20 E70T-7 EN ISO 17632-B T 49 Y T7-0 NO A |

| [F]OW-S50T | All | AWS A5.20 E71T-GS |

Tables 2 and 3 show the chemical compositions and mechanical properties of all-deposited metals by [F]OW-S50P, respectively.

| C | Si | Mn | P | S | Al |

|---|---|---|---|---|---|

| 0.14 | 0.20 | 0.85 | 0.015 | 0.002 | 0.65 |

| YS (MPa) | TS (MPa) | El (%) | vE-30℃ (J) |

|---|---|---|---|

| 440 | 560 | 27 | 105 |

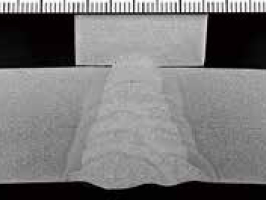

[F]OW-S50P provides excellent bead shape and penetration in all positions. Figure 1 shows the results of butt joint welding in the horizontal, vertical upward and overhead positions.

| Horizontal position welding | Vertical upward position welding | Overhead position welding |

|---|---|---|

YS: 471 MPa TS: 563 MPa vE-30℃: 61 J |

YS: 441 MPa TS: 545 MPa vE-30℃: 67 J |

YS: 429 MPa TS: 534 MPa vE-30℃: 74 J |

Figure 1: Results of butt joint welding in all positions by [F]OW-S50P

![Figure 2: Optimum range of arc voltage by [F]OW-S50P](../../images/products/product-spotlight/spotlight06_01.png)

Figure 2: Optimum range of arc voltage by [F]OW-S50P

It can be used for welding 490 MPa (70 ksi) class high tensile strength steels as it has excellent notch toughness down to -30 °C min. Furthermore, good porosity resistance against wind speeds as high as 10 m/sec makes welding in strong outdoor winds possible.

However, maintaining the arc voltage within the optimum range is necessary; because porosity defects are likely under the welding conditions exceeding the optimum range of arc voltage as well as arc length as shown in Figure 2.

Products

- Main Products

- Welding Consumables

- Arc welding robots

- Industries - Recommended Materials

- Welding Handbook Quick View

- Product Quick View & Highlights

- For HEAT-RESISTANT STEEL

- For STAINLESS STEEL

- For LOW-TEMPERATURE STEEL

- Product Highlight

- Catalog

- Technical Highlights

- Certification

- SDS ※English Only

- ARCMAN

- Welding Robot

- Software